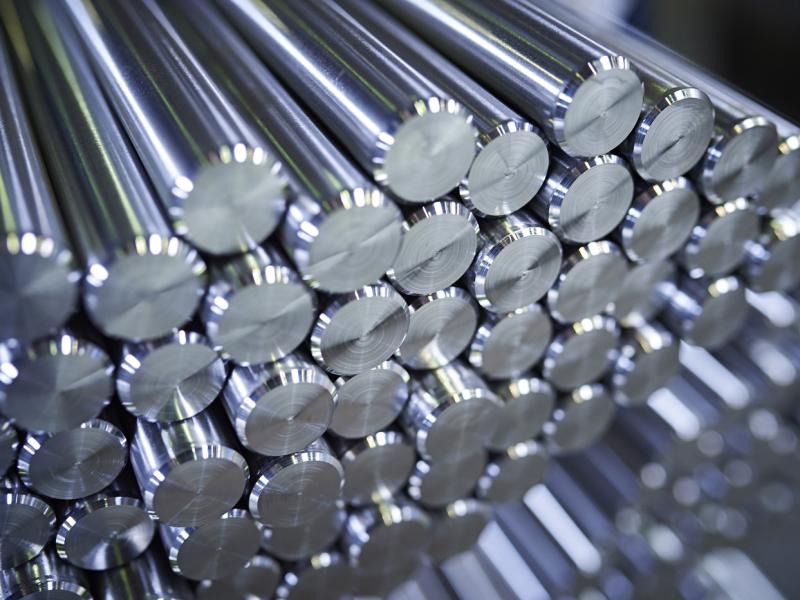

HOT WORK TOOL STEEL H19

Chromium hot-work device steels, classified as H steels under the AISI system, range from H1 to H19, with each grade tailored for specific applications. H19 steel stands out due to its excellent abrasion and wear resistance, attributed to its vanadium content. This makes it ideal for challenging hot-work tooling tasks like brass extrusion tooling, brass die-casting dies, and other high-temperature, high-stress environments requiring exceptional durability and performance.

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon,C | 0.32-0.45 |

| Manganese, Mn | 0.20-0.50 |

| Silicon, Si | 0.20-0.50 |

| Molybdenum, Mo | 0.30-0.55 |

| Chromium,Cr | 4.00-4.75 |

| Vanadium, V | 1.75-2.20 |

| Copper,Cu | 0.25 |

| Phosphorous, P | 0.03 |

| Sulfur, S | 0.03 |

| W | 3.75-4.50 |

| Nickel,Ni | 0.3 |

| Co | 4.00-4.50 |

PHYSICAL PROPERTIES

| Properties | Conditions |

|

|---|---|---|

| Carbon, C | 0.32-0.45 | Column 3 Value |

MECHANICAL PROPERTIES

| Properties | Metric | Imperial |

|---|---|---|

| Hardness, Rockwell C (air cooled from 1204°C; 704°C temper temperature) | 41 | 41 |

| Hardness, Rockwell C (air cooled from 1204°C; 482°C temper temperature) | 57 | 57 |

| Hardness, Rockwell C (air cooled from 1204°C; 530°C temper temperature) | 58 | 58 |

| Machinability (1% carbon steel) | 55.0 – 60.0% | 55.0 – 60.0% |

THERMAL PROPERTIES

| Properties | Condition | |

|---|---|---|

| Thermal expansion (@20-100ºC/68-212ºF) | 11 x 10-6/ºC | 20-100ºC |

FEATURES :

- Heat Treatment

- Forging

- Annealing

- Martempering

- Final Grinding

- Hardening

- Stress Relieving

contact us today

- Corporate Location – 2nd Floor, Amber Gem Tower, Ajman UAE

- +971 542848454

- info@eliteeximuae.com